PolyFlex TPU95 2.85mm 750g

Write a review

R569.00 Original price was: R569.00.R455.20Current price is: R455.20.

PolyFlex™ TPU95 is a thermoplastic polyurethane (TPU) based filament specifically engineered to work on most desktop 3D printers. It has a shore hardness of 95A and can stretch more than 3 times its original length.

Related products

Related products

-

Add to basket This product has multiple variants. The options may be chosen on the product page

Creality Standard Resin Plus – 1000g

R599.00 -

Add to basket This product has multiple variants. The options may be chosen on the product page

Recreus PETG Filament 1.75mm 750g

R595.00 -

Add to basket This product has multiple variants. The options may be chosen on the product page

Creality Standard Resin – 1000g

R649.00 -

Add to basket This product has multiple variants. The options may be chosen on the product page

PolyLite PLA 1.75mm 1kg

R349.00

Applications

PolyFlex™ TPU95 is a thermoplastic polyurethane (TPU) based filament specifically engineered to work on most desktop 3D printers. It has a shore hardness of 95A and can stretch more than 3 times its original length.

What does 95 means?

95 refers to the shore hardness of the material: 95 Shore A.

In 3D printing the shore hardness is only an indication on how flexible the printed part will be. However it is important to also take in consideration the infill percentage, number of walls, top/bottom layers and the layer height.

Can my printer print PolyFlex™ TPU95?

We highly recommend using a direct drive printer to print PolyFlex™ TPU95. A direct drive printer is a printer with an extruder mounted on top of the hot end.

Printing Settings

| Printing Temperature: | 210˚C – 230˚C |

| Bed Temperature: | 25˚C – 60˚C |

| Printing Speed: | 20mm/s -40mm/s |

| Fan: | ON |

| Direct Drive Retraction Distance: | 3mm |

| Direct Drive Retraction Speed: | 40mm/s |

| Indirect Drive Retraction Distance: | 6mm |

| Indirect Drive Retraction Speed: | 60mm |

| Recommended Support Materials: |

PolyDissolve™ S1/PolySupport™

|

| Dry Settings: | 65˚C for 8h |

|

(Only if the material has absorbed moisture)

|

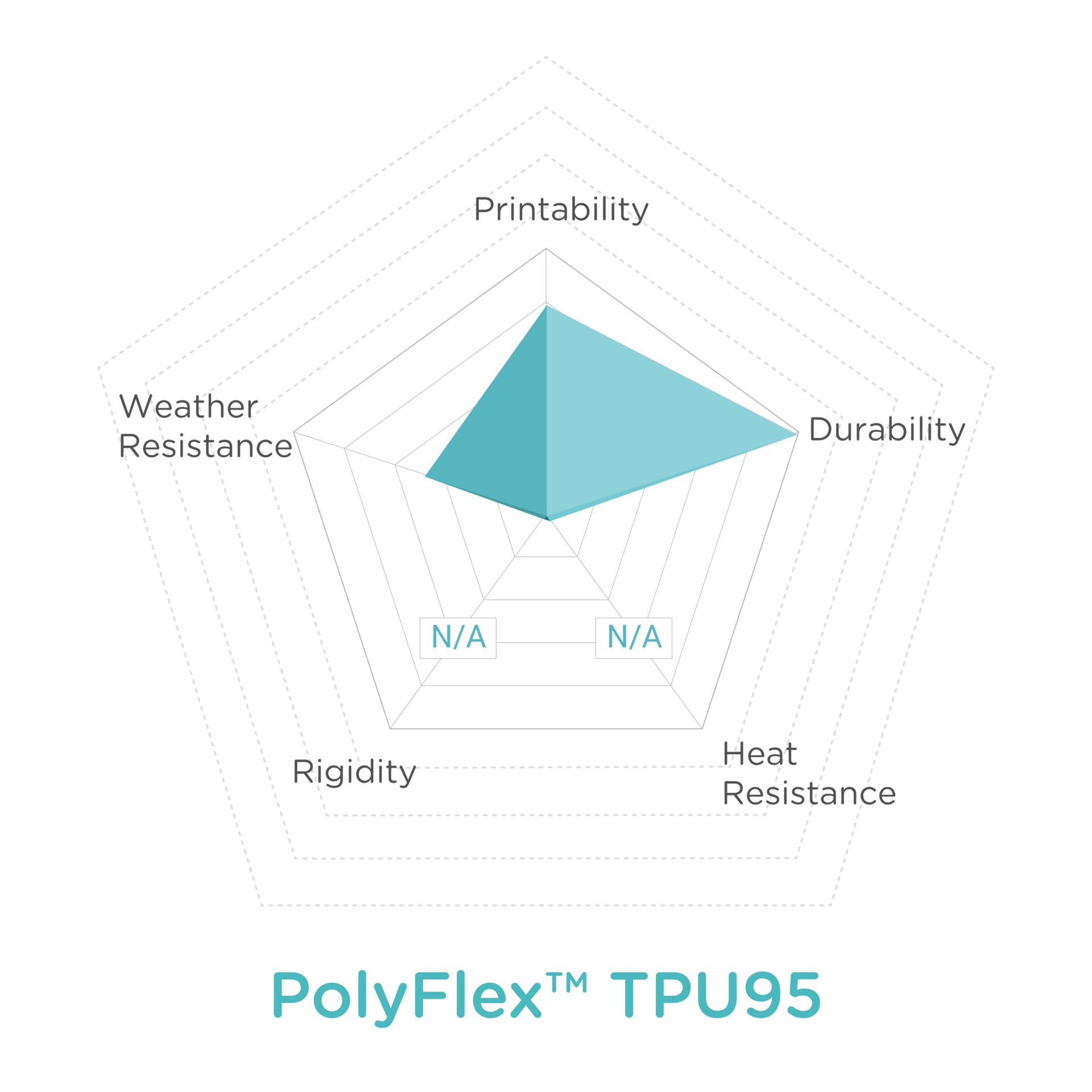

Material Properties

Let our Team guide you on purchasing the correct 3D equipment and materials for your next project by contacting us directly https://ec3d.co.za/contact-us/

| Weight | 1 kg |

|---|---|

| Dimensions | 21 × 21 × 7 cm |

| Colour | |

| Brand | |

| Filament Diameter | |

| Material Type | |

| Machine Type | |

| Weight |